Goepel Products, Training & Support

Goepel Embedded JTAG Solutions

Embedded Board Test

Embedded Board Test describes a test method for modern electronics, using the intelligence of built-in circuits.

Embedded Programming

Oe solution for all programming requirements of modern electronics using already available on-board resources – in development or production.

Embedded Functional Test

Functional test of modern electronics using the native component intelligence - realized by Embedded Functional Test.

The Complete Embedded JTAG Solution

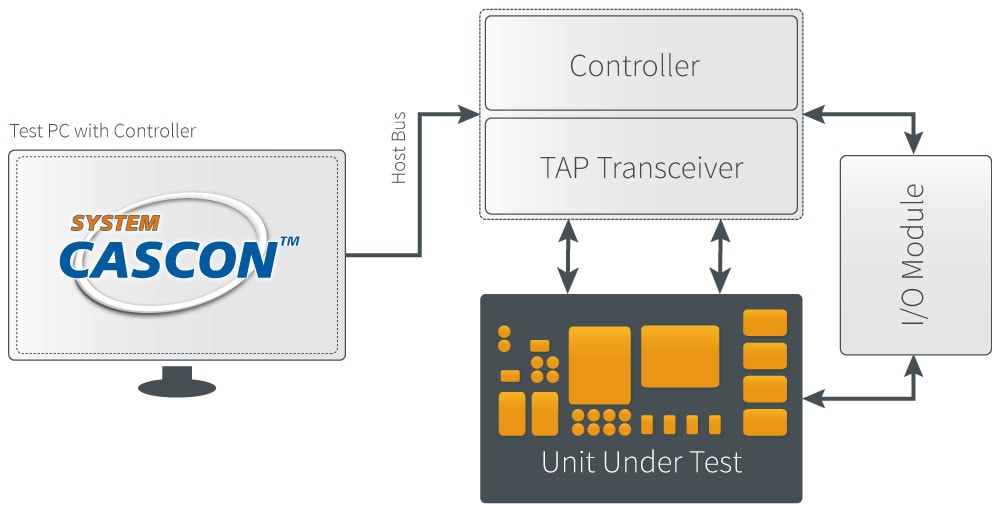

Boundary Scan is an electrical test method, detecting structural errors in circuits. Scan test essentially means “testing at the periphery (boundaries) of a circuit”.In order to implement this sort of testing, GOEPEL electronic has developed the principle of interaction of various hardware components – interplay between Controller, I/O Module, Tap Transceiver & UUT.

Embedded Board Test

Embedded Board Test describes a test method for modern electronics, using the intelligence of built-in circuits. Various technologies are used, having one thing in common: both generation and application of the test scenarios takes place in one system. The test system consists of a unique, modular control hardware and software.

Embedded Board Test allows digital, static test of pins and networks. Functional tests can also be integrated. These include access to I2C and SPI components, measurement and evaluation of analog processor inputs, dynamic memory tests and test of high-speed interfaces (e.g. USB 3.0.).

Typical production faults such as short circuits, missing resistors, non-soldered pins and BGA balls, but also errors in high-speed data transmission are can be found quickly and efficiently. The short execution time and accurate fault diagnosis allow cost-optimized repair..

Embedded Programming

The idea behind Embedded Programming is to offer one solution for all programming requirements of modern electronics using already available on-board resources – whether used in development or in production. A universal programming system today must support several scenarios. On-board programming distinguishes between the programming of serial Flash devices (I²C, SPI) and the programming of parallel Flashes (NOR, NAND). In addition, more and more data must be written into on-chip Flash memory. This often involves processors, controllers, or FPGAs. Users in production are encountering increasing demand to carry out these programming requirements in parallel on several boards.

The Embedded Programming solution implements all these requirements in one system.

The hardware and software used in this process is so flexible that the user can adapt the system at any time. This makes it possible to easily meet the requirements for smaller or larger batches, shorter cycle times, etc.

Embedded Functional Test

Functional test of modern electronics using the native component intelligence - realized by Embedded Functional Test. The creation and application of test scenarios takes place entirely in a system, which is formed by a common control hardware and a common control software.

Embedded Functional Test allows the integration of functional tests such as access to I2C and SPI components, measurement and evaluation of analog processor inputs, dynamic memory tests and test of high-speed interfaces (e.g. USB 3.0.). Typically these tests are used as an extension to existing structural tests (Boundary Scan, ICT or Flying Probe).

The Embedded Functional Test also detects errors in the dynamic range, which is not possible with purely statistic tests in the normal case. In contrast to the classical function test, no board-specific firmware is required.

Support & Training